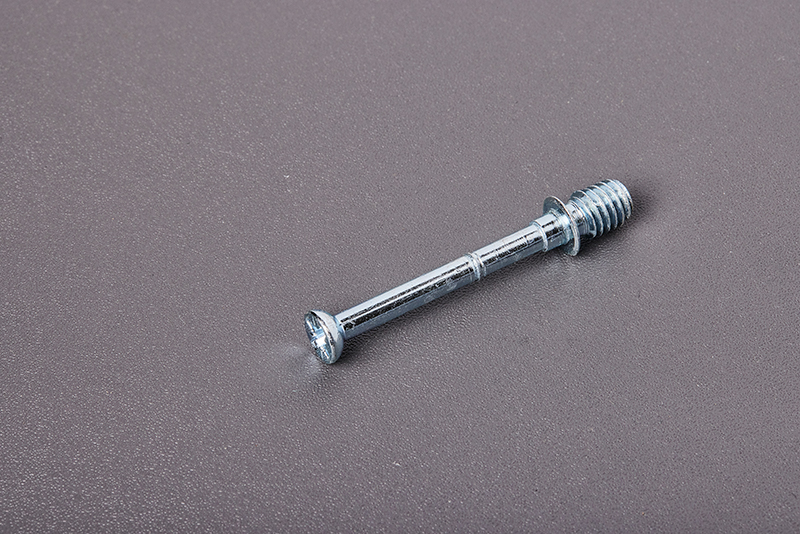

42 M6*8mm machine-thread metal connecting rod

The connecting rod is the main component of the three-in-one product. According to the structure, it can be divided into: thread (intermediate) main body, neck, head.

1 Thread: The connecting rod is divided into self-tapping and machine-threading according to the different plates to be installed. Self-tapping is mainly suitable for high-density plates. The screws can withstand large tensile forces. Requires pre-embedding or installation of quick-loading plastic bushes . The machine-thread are suitable for all plates, but the embedded nuts or quick-loading plastic bushes must be added to the plates.

2 Main body guide: The guide part of the connecting rod is divided into metal rod and plastic-coated rod according to the different requirements of customers. 3 Neck and head: Different classification according to the shape of the opening.

1 This connecting rod is an M6 cross- countersunk head with metal wire teeth. M6*34+8mm wire teeth is the very common size, which is widely used in furniture installation in China and around the world. It is suitable for various types of plates, and it is necessary to add embedded nuts or quick-loading rubber particles on the plate during installation.As the largest enterprise in China for connecting rods. Our company uses a fully automated production line, with a daily output of 500,0000 pieces,

2 Main parameters : M6*8mm machine-thread metal connecting rod

| Name | 42 M6*8 metal connecting rod |

| length | 42MM |

| Installation length | 34mm |

| Length of thread | 8MM |

| Finish | Blue zinc or colourful zinc finish |

| Shape of head | Cross-Countersunk head |

| Thread | Machine-thread |

| Material | Steel |

3 Customer rights: free samples, free salt spray test report and tensile test report

4 Quality certification system: ISO90001 //CE + certificate picture